3D High Performance Resin - Rigid Ceramic - High quality filaments

4.9 (131) · € 16.50 · En Stock

High quality 3D High Performance Resin - Rigid Ceramic . Worldwide shipping with UPS & FedEx. One-stop shop for 3D printing materials. Ordered before 15h CET? Ships same business day

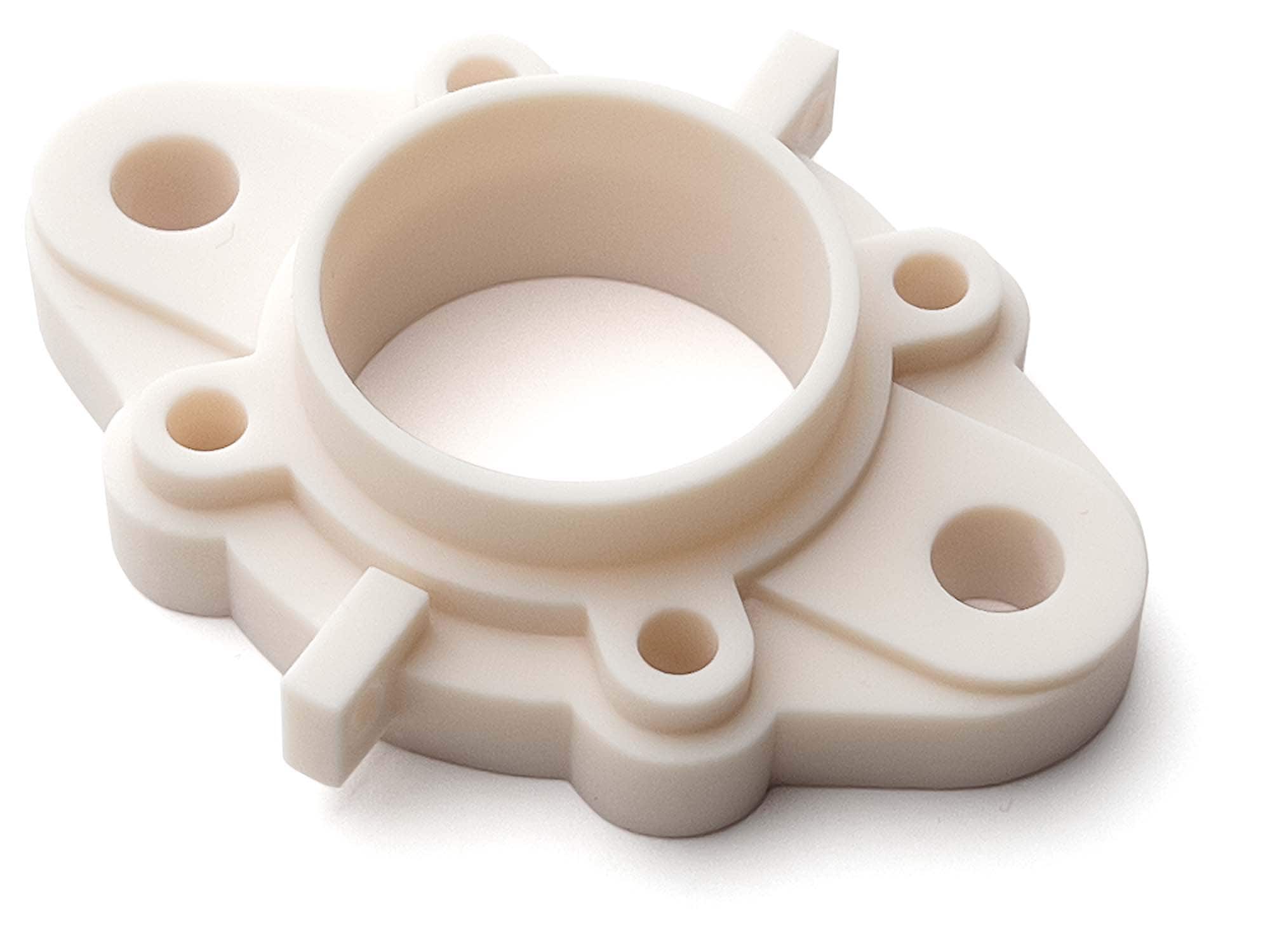

Our High Performance Resin - Rigid Ceramic has been reinforced with durable nanoparticle ceramics. This makes it one of the stiffest and strongest materials available on the market. A flexural modules of 9.5 GPa and a maximum flexural strength of 170 MPa can be obtained. Parts made with this resin feature an impressive resistance to bending under high loads.

Next to this, the material has excellent chemical and heat resistance properties. The resin prints with an incredibly high resolution and parts printed with the resin have a smooth matte finish.

Important key features

Reinforced with durable nanoparticle ceramics

A superb maximum flexural modulus of 9.5 GPa

A superb flexural strenght up to 170 MPa

Dimensionally stable under load

Strong chemical resistance

Good thermal resistance

Good compatibility with all SLA, DLP and LCD / MSLA 3D printers in the range of 385 – 420nm

Suitable applications

Suitable for rapid industrial-grade prototyping

Suitable for fabricating electrical casings

Suitable for making fluid flow components

Suitable for creating aerodynamic test models

Suitable for 3D printing short-run injection molds

Preparation(s) before starting to print

Shake the bottle for at least 2 minutes before each use.

After shaking the bottle, leave the resin to rest for 10 minutes to let air bubbles get out of the resin

The resin can be poured back from the vat into the bottle once your print is finished

Always use protective measurements like safety glasses and nitrile gloves when handling resins.

Post-processing

We do advise you to post-process your 3D print in order to achieve the material properties

Rinse your 3D printed object in IPA or (Bio)Ethanol for approximately 5-10 minutes

An ultrasonic cleaner is preferred/recommended

Make sure that IPA and/or (Bio)Ethanol rinsed objects are perfectly dry before further post-curing to prevent warping or cracking.

Place the rinsed parts in a well-ventilated area for at least 4 hours, or use pressurized air for at least 5 minutes

Cure your object in a high power curing chamber (like the CUREbox™ Plus) for approximately 60 minutes at 65°C

And after that approximately 2 hours of thermal curing at 100°C. The preferred curing wavelength is between 300-410nm

Safety

Please always be aware that when 3D printing with resins that you are working with chemicals and that you should always be cautious and use the personal protective equipment as stipulated in our safety data sheets.

Always wear Respiratory Protection when sanding/cutting the resin object.

Always use nitrile gloves when handling resins and uncured resin objects.

Print settings

Please see below some basic print settings for a variety of wide used printers.

Phrozen Sonic Mini 4K

50µm

First / Burn-in Layers: 2x to 4x for 70 to 75 Seconds

Normal Layers: 7 to 9 Seconds

Anycubic Photon

50µm

First / Burn-in Layers: 4x to 3x for 110 to 120 Seconds

Normal Layers: 16 to 18 Seconds

Light-off Delay: 1

Bottom Light-off Delay: 2

Anycubic Photon Mono SE

50µm

First / Burn-in Layers: 4x to 6x for 65 to 75 Seconds

Normal Layers: 6.5 to 7.5 Seconds

Lifting Distance: 8mm

Light-off Delay: 0.5

Bottom Light-off Delay: 3

Anycubic Photon Mono X

50µm

First / Burn-in Layers: 3x to 5x for 75 to 80 Seconds

Normal Layers: 5.5 to 7 Seconds

Lifting Distance: 8mm

Light-off Delay: 1

Bottom Light-off Delay: 3

UV Power: 85 ~ 90%

*If you need the best settings for your 3d printer we highly recommend using the included RERF (Resin Exposure Range Finder) or Resin Exposure Calibration Tool.

This is most likely included with the 3d printer usb stick and or manual.

Product export information

HS Code: 2916140090

Description: Resin for 3D Printing

Country of origin: the Netherlands

High Performance Series – Rigid Ceramic Resin

Materials, Free Full-Text

What Materials Are Used in the 3D Printing Process?

TOUGH AND STRONG: Tough Pro PLA+ is designed for your most demanding projects but prints smoothly and without fuss making it perfect for quick jobs.

3D-Fuel 3D Filament High Temp Tough Pro PLA+ Almond, 1.75mm, 1 kg +/- 0.02mm Tolerance, Made in USA, Easy to Print and Works with Most 3D Printer

Phrozen Loctite Onyx Pro 410 Rigid Resin • 3D Printer Store

Heat-Resistant 3D Printing Materials Guide: Compare Processes

Ultracur3D® RG 35 Rigid Photopolymer Material

The Best 3D Printer Filaments of 2023 – Buyer's Guide

FormFutura HDGlass PETG 3D Filament - 3D Printlife

SunLu PLA Filament 1.75mm, Rainbow, 1kg

Whats The Latest in 3D Printing Materials

Conjure Tough Non brittle resin for miniatures - ChiTu Systems!